3D-printed food could be the future of cooking, according to a study published in the journal Nature. The technology enables users greater control over their meals, reducing food-borne illness risks and cutting costs. The researchers 3D-printed and laser-baked a seven-ingredient cheesecake, which tasted different from a conventional cheesecake as the ingredients were compartmentalized in many pockets within the structure. Blutinger, the lead author, believes his printer’s software is innovative and can follow complex recipes and move the robot in intricate patterns. It is also notable for being able to cook the food it produces with the use of a laser. Although the technology has some limitations, including requiring all ingredients to be in paste form, Blutinger hopes that his research inspires more investment.

The Future of Food? Scientists 3D-Print Cheesecake

A study recently published in the journal Nature has showcased modern food-printing technology, including the successful 3D-printing and laser-baking of a seven-ingredient cheesecake. The researchers suggest that food-printing could provide greater control over the nutrition of meals, reduce the risk of food-borne illnesses, and cut costs.

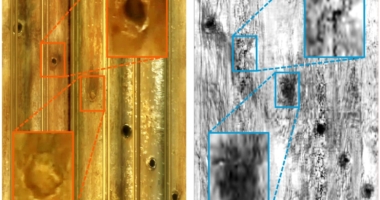

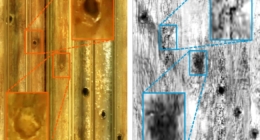

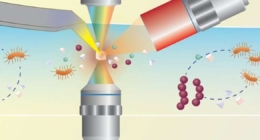

The food printer, designed by Jonathan Blutinger, a robotics engineer from Columbia University’s Creative Machines Lab, functions like a standard 3D printer, equipped with a laser for baking and extruding blobs of peanut butter and fruit puree, rather than molten plastic. Blutinger explains that the printer’s software is the real innovation, as it enables the machine to follow complex recipes and move the robot in precise, intricate patterns.

Food-printing does have its limitations, however. All the ingredients must be in a paste form that can be squeezed through the printer. For now, the printer is compatible only with pastes and liquid sprays. Blutinger and his team are working on making it compatible with powders as well.

Creating a structurally-sound cheesecake from paste comes with unique difficulties. The researchers had to create compartments from harder or more viscous ingredients first to support the softer paste within, similar to building a house. The final product tasted “very sweet,” unlike any cheesecake that one researcher had tasted before.

Blutinger believes that food-printing will bring us closer to food, allowing us to control all the base elements of a dish. It also enables users to see their meals being created right in front of them and to dial up or scale down every micro or macronutrient they want.

While food-printing is not without its challenges, its proponents argue that it could be the future of food preparation, making cooking as simple as hitting a button to “print” a meal.

3D-Printed Food: The Future of Cooking?

A recent study published in the journal Nature revealed the capabilities of modern food-printing technology. The research team succeeded in 3D-printing and laser-baking a seven-ingredient cheesecake, which tasted like a peanut butter and jelly sandwich, although it didn’t have cream cheese. According to the researchers, the technology allows users greater control over the nutrition of their meals, reduces the risk of food-borne illness, cuts down on costs, and can reduce food waste.

Blutinger, the lead author and a robotics engineer from Columbia University’s Creative Machines Lab, believes 3D-printing could make a big impact on the plant-based meats industry since it allows finer control over the distribution of ingredients. His printer can cook the food it produces with the use of a laser, which is a significant step forward for 3D food printing as it deals with various ingredients requiring different degrees of targeted heating. Lasers are ideal because of their high level of control and precise targeting.

Blutinger’s team believes that the 3D printer may become a staple home and industrial cooking device as the technology rapidly develops. High-end restaurants have already embraced the technology, including U.K.-based Food Ink, Michelin-starred Mélisse Restaurant in Santa Monica, Calif., and La Enoteca and La Boscana in Spain.

While other companies have debuted food printing technology, Blutinger’s printer stands out because of its software that can follow complex recipes and move the robot in precise, intricate patterns. Despite its limitations, such as requiring all ingredients to be in paste form, Blutinger hopes that his research inspires more people to invest in the technology.

Blutinger believes that software is the key to improving the food industry, and when software touches an industry, it never looks back.

Don’t miss interesting posts on Famousbio