BMW is taking digital-first approach to validate and optimize complex manufacturing systems across its production network using NVIDIA Omniverse Enterprise. Tier-two automotive parts suppliers, many of which are SMEs, are slower to automate fully, however, as robots become smaller, more adaptable, easier to program, and less capital-intensive, this is expected to change. BMW has taken factory planning to new heights by planning and validating its Debrecen plant completely virtually. NVIDIA Omniverse makes collaboration across sites and time zones easier and supports the planning and design of structures, production systems and processes at an entirely new technological level. In the future, all the relevant product, process, quality and cost data will also gradually be available in Omniverse. In autonomous and self-driving vehicle news, several companies are making developments, including Safe Kids, Kodiak, Navya, REE, Arbe, RoboSense, Veoneer, AImotive, MINIEYE, Blickfeld and Webasto.

In the latest news related to autonomous and self-driving vehicles, Waymo, Torc Robotics, aiMotive, Applied Intuition, Mercedes-Benz, and BMW are the prominent names. Recently, aiMotive, which is known for its advanced automotive technology solutions, has partnered with RenderPeople, a company that boasts the most comprehensive library of photorealistic human 3D models.

The collaboration between aiMotive and RenderPeople is aimed at providing development teams with high-fidelity human models, such as pedestrians, construction workers, children playing on the sidewalk, and more. By using RenderPeople’s library of more than 4500 human 3D models in different product lines, aiMotive can quickly populate its aiSim’s virtual environments with realistic 3D assets. This move will help create more realistic virtual test scenarios and synthetic training data with greater diversity and realism.

RenderPeople has been a go-to source for CGI professionals for almost 10 years, providing them with hyper-realistic and vivid visualizations for a range of applications. aiMotive’s industry-leading technology provides a perfect opportunity for RenderPeople to expand its expertise and extensive 3D asset library into the simulation and computer vision industry. The availability of high-quality 3D human assets is critical to the development and augmentation of synthetic data or running simulations, and it allows developers worldwide to advance important technologies such as autonomous driving.

Dániel Tósoki, the Product Manager of aiSim, has stated that they are grateful to work with best-in-class partners who can provide added value to aiSim’s users by enriching their existing offering. He believes that RenderPeople’s comprehensive set of high-fidelity human assets is a natural extension to aiSim, as simulating pedestrians with realism and diversity is becoming increasingly important to their customers globally.

According to Lukas Lamprecht, CEO of RenderPeople, their products can take synthetic data generation and simulation applications to a whole new level of reality. Collaborating with a highly innovative and world-leading developer like aiMotive enables them to make their products accessible to a new industry and contribute significantly to shaping critical technologies that will have a lasting effect on how humans and technology interact.

Furthermore, Applied Intuition, which is another autonomous vehicle technology company, has acquired SceneBox. This move is aimed at providing a complete solution for simulation-based development and testing of autonomous vehicles. With the acquisition of SceneBox, Applied Intuition can create a comprehensive platform that enables automotive companies to design, develop, and validate their autonomous driving systems more efficiently. The acquisition also allows Applied Intuition to expand its customer base and better support customers in the development of autonomous driving solutions.

Applied Intuition, Inc., a provider of simulation and software for autonomous vehicle (AV) development, has acquired SceneBox, a data management and operations platform designed for machine learning (ML). SceneBox enables engineers to train better and more accurate ML models using a data-centric approach. The platform offers a rich web interface, extensive APIs, and advanced features like embedding-based search. Its features enable engineers to explore, curate, and compare datasets rapidly, diagnose problems, and orchestrate complex data operations. With the acquisition of SceneBox, Applied Intuition can create a comprehensive platform that allows automotive companies to design, develop and validate their autonomous driving systems more efficiently.

Markus Schäfer, the CTO of Mercedes-Benz, recently attended the 2023 South By Southwest® (SXSW®) Conference to discuss the future and current state of automated driving with its technology partners, Austin Russell, CEO and founder of Luminar, and RJ, CEO of ZYNC. Attendees learned how automotive technology is enriching customers’ lives by providing more time for the things they love, such as connecting with friends and family, listening to music, or watching movies.

Mercedes-Benz’s DRIVE PILOT, which was launched in Germany in May 2022 and will be introduced to U.S. roads in Nevada and California later this year, is a conditionally automated driving system that provides customers with valuable time. Markus Schäfer explained how the chip-to-cloud architecture is seamlessly integrated with timeless automotive design, enabling the safety, security, scalability, and connectivity necessary for future automated driving and infotainment features.

Torc Robotics, an independent subsidiary of Daimler Truck AG and a leader in commercializing self-driving vehicle technology, has signed an agreement to acquire Algolux Inc. Algolux’s expertise and award-winning intellectual property in computer vision and machine learning are the main reasons for Torc’s acquisition.

According to Joanna Buttler, the Head of Autonomous Technology Group at Daimler Truck AG, Algolux’s perception capabilities can bring the company closer to its goal of safely and reliably bringing SAE Level 4 autonomous trucks into series production in the USA within this decade. The acquisition will help Torc strengthen key capabilities for its commercialization of Level 4 autonomous trucking.

Allan Benchetrit, Algolux’s president and CEO, said that joining forces with Torc makes sense because both companies share a commitment to creating robust technology to realize the potential of autonomy and help save lives. Algolux’s established team with deep expertise in Artificial Intelligence/Machine Learning (AI/ML) talent and perception complements Torc’s already experienced engineering team.

Algolux has been recognized for excellence in its field and has been named to the 2021 CB Insights AI 100 List of the world’s most innovative artificial intelligence startups. Torc has been working with Algolux for over a year on multiple perception concepts and methods for robustly improving object detection and distance estimation. Algolux’s software is currently operating on initial Freightliner Cascadia test vehicles in the U.S. and is being included in areas of Torc’s software development efforts.

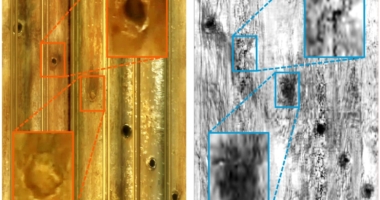

Robust perception technology is critical to helping Torc’s autonomous system correctly identify objects in challenging visual conditions such as low light, fog, or inclement weather. Algolux’s technology, which is at the intersection of deep learning, computer vision, and computational imaging, will help Torc improve its perception capabilities.

Felix Heide, Algolux’s CTO, stated that the acquisition brings together Algolux’s end-to-end AI stack, from photons to behavior, with Torc’s pioneering autonomous technology. He added that the combination of Algolux’s technology and Torc’s tightly integrated OEM truck platform will help bring to market a commercially viable, safety-critical long-haul trucking application at scale.

Torc Robotics acquires Algolux Inc.

Torc Robotics, an autonomous driving technology provider, has announced that it will acquire Algolux, an expert in machine learning and computer vision. Algolux’s proven expertise and award-winning intellectual property will be integrated into Torc’s capabilities to develop its autonomous trucks. The acquisition will enhance Torc’s object detection and distance estimation abilities, enabling it to improve perception technology in low light, fog, and other difficult visual conditions. Algolux’s software is currently being used on initial Freightliner Cascadia test vehicles in the US and is part of Torc’s software development efforts. The transaction is set to be completed after the parties have completed pre-closing activities, including any required approvals.

Waymo’s Safety Framework for Autonomous Vehicles

Waymo, a self-driving technology company, recently published a new paper that outlines the company’s approach to building a reliable case for safety, a thorough blueprint for use by any company developing fully autonomous driving systems. Waymo’s established safety framework assesses the safety of technology and operations and guides the deployment of the Waymo Driver, enabling the company to offer the world’s first fully autonomous ride-hail service, Waymo One. The company has also expanded its 24/7 operations with no human driver across multiple major US cities, allowing residents of Metro Phoenix and San Francisco to commute, run errands, meet friends and get a safe ride home as part of their daily lives. Waymo hopes to deepen its dialogue with policymakers and regulators by sharing information about its safety methodologies and safety performance data, and to encourage greater transparency across the industry.

Automotive Industry Leading in Robotics

The automotive industry has the largest number of robots working in factories around the world, with operational stock reaching a record one million units. Robot density, which indicates the level of automation in the top car producing economies, is highest in the Republic of Korea, with 2,867 industrial robots per 10,000 employees in operation in 2021. Germany ranks second with 1,500 units, followed by the United States, counting 1,457 units, and Japan, with 1,422 units per 10,000 workers. China, the world’s biggest car manufacturer, has a robot density of 772 units, but this is increasing rapidly. In 2021, new robot installations in the Chinese automotive industry almost doubled to 61,598 units, accounting for 52% of the total 119,405 units installed in factories worldwide. The growing demand for electric vehicles has also increased automation in the industry. The European Union has announced plans to end the sale of air-polluting vehicles by 2035, and the US government aims to reach a voluntary goal of 50% market share for electric vehicle sales by 2030.

BMW’s Latest Milestone in Digitalising Automotive Manufacturing

BMW Group, in partnership with NVIDIA, has set a new milestone in the digitalisation of automotive manufacturing with its latest plant in Debrecen, Hungary. The ground-breaking and innovative planning concept for the future plant Debrecen, scheduled to open in 2025, has been entirely realised and validated virtually, two years ahead of its official launch. Debrecen will produce BMW Group’s next generation of all-electric models – the Neue Klasse.

BMW Group is taking a digital-first approach to validate and optimise complex manufacturing systems across its production network. It is using NVIDIA Omniverse Enterprise, a platform for building and operating 3D industrial metaverse applications, to run real-time digital twin simulations to optimise layouts, robotics and logistic systems virtually. Omniverse will be extended across the BMW product network globally.

Milan Nedeljković, a member of the Board of Management of BMW AG, responsible for Production, described the digital twin as consolidating various planning systems, allowing teams worldwide to collaborate in real-time and make quicker and more informed decisions. By using this approach, BMW can save time and costs, increasing efficiency throughout its production network.

Jensen Huang, founder and CEO of NVIDIA, said, “We are partnering closely with BMW, using NVIDIA Omniverse to help streamline their manufacturing processes, enhance collaboration and further efficiency. Our collaboration will continue to push the frontiers of virtual integration for the next generation of smart, connected factories around the world.”

Virtualisation, Robotics and Artificial Intelligence in Automotive Manufacturing

The automotive industry has the largest number of robots working in factories worldwide, with operational stock reaching one million units. Most automotive manufacturers have invested in traditional “caged” industrial robots for basic assembling and are now investing in collaborative applications for final assembly and finishing tasks. Tier-two automotive parts suppliers, many of which are SMEs, are slower to automate fully. However, as robots become smaller, more adaptable, easier to program, and less capital-intensive, this is expected to change.

China, the world’s biggest car manufacturer, has a robot density of 772 units, with new robot installations almost doubling to 61,598 units in 2021, accounting for 52% of the total 119,405 units installed in factories worldwide. The automotive industry is forced to invest in ambitious political targets for electric vehicles. The EU aims to end the sale of air-polluting vehicles by 2035. The US government aims to reach a voluntary goal of 50% market share for electric vehicle sales by 2030. All new vehicles sold in China must be powered by “new energy” by 2035, with half of them being electric, fuel cell or plug-in hybrid, and the remaining 50% hybrid vehicles.

BMW Group and NVIDIA’s Virtual Planning Collaboration

BMW Group, in collaboration with NVIDIA, has developed a comprehensive virtual planning system for vehicle manufacturing processes. The new planning approach is being executed at the company’s first facility to be planned and validated completely virtually in Debrecen, Hungary. The BMW Group has partnered with NVIDIA Omniverse to build and operate 3D industrial metaverse applications. Omniverse works as a “cockpit” offering easy access to BMW’s digital planning worlds. It supports the planning and design of structures, production systems, and processes at an entirely new technological level. Virtual planning facilitates global collaboration and is expected to save costs and increase efficiency. The virtual planning approach is now considered a blueprint for all future planning processes at BMW Group, and consistent virtual planning is the next important step in the transformation to the BMW iFACTORY. The concept of iFACTORY was first introduced in early 2022, and the Neue Klasse, based on a completely new vehicle architecture, heralds the fundamental transformation of production to the BMW iFACTORY.

BMW is accelerating its digital transformation of automotive manufacturing by using virtual planning to facilitate global collaboration. The BMW Group’s first facility to be planned and validated completely virtually is the future plant Debrecen, where vehicle manufacturing is already underway more than two years before the official launch of series production. The concept of the iFACTORY, which is described by Milan Nedeljković as “our masterplan for the automotive production of tomorrow”, was first introduced in early 2022. The Neue Klasse heralds the fundamental transformation of production to the BMW iFACTORY. Virtual planning facilitates global collaboration, and the NVIDIA Omniverse platform is used to validate and optimize complex manufacturing systems across the BMW production network, offering quick, easy access to the digital planning worlds of BMW. The platform enables the real-time collaboration between different BMW Group planning departments and their partners, delivered on NVIDIA’s Omniverse, which had enabled the first virtual start of production.

Virtual planning is under way for the roughly 1.4 km2 production hall for the Neue Klasse in Debrecen, where the success of the virtual start of production is a testament to the high standards that can be achieved through the digitalization of the planning process. NVIDIA Omniverse allows production experts to use live data both in-house and with suppliers on the detailed planning and optimization of processes and individual systems without compatibility issues. It makes structure and facility data easy to retrieve and integrate with equipment and assembly line data. The platform also will allow suppliers to be involved in decision-making and integrates the tried-and-tested design and planning tools that BMW has been using to date.

Over time, all the relevant product, process, quality, and cost data will also gradually be available in Omniverse alongside the development, planning, and production processes. There will also be further developments to the platform, which are expected to include “invisible” processes such as the consumption of energy and resources. Omniverse will enhance digital operations as well – a crucial stage that is already being tackled by BMW Group and NVIDIA teams.

In autonomous and self-driving vehicle news, Velodyne Lidar announced a three-year agreement with EasyMile, a global leader in driverless technology and smart vehicle solutions, to use Velodyne lidar sensors in the production of its EZ10 autonomous passenger shuttles. Chevy Super Cruise driver assistance technology will launch on the Sierra 1500 Denali in late model year 2022.

The article discusses the involvement of various companies in autonomous and self-driving vehicle news. The focus is on safety advocates who are working to protect children in AVs. The companies mentioned in the article include Safe Kids, Kodiak, Navya, REE, Arbe, RoboSense, Veoneer, AImotive, MINIEYE, Blickfeld, and Webasto.

Don’t miss interesting posts on Famousbio