METTLER TOLEDO has launched a new portfolio of automated inspection technology for food manufacturers. The new offering includes advanced smart cameras and label inspection systems for efficient and reliable inspection of product labels and prints. The technology inspects 100% of products and shapes and identifies 100% of label data and quality challenges, reducing manual spot checks and achieving documented label inspection in line with industry guidelines such as BRCGS to support consumer safety and prevent recalls and expensive retailer fines. The new portfolio includes the V13 Flat Pack Label Inspection system, CV Combination, and CMV Combination, which offer space-saving and fully flexible solutions that can be integrated into existing production lines. Additionally, the technology can be retrofitted onto existing Mettler-Toledo equipment, offering considerable space savings. The software is particularly user-friendly, featuring a dedicated toolset for label inspection that helps with product set-up, making it easy to use. Overall, the new portfolio offers a cost-effective way for manufacturers to improve their label inspection process while ensuring consumer safety and avoiding expensive retailer fines and recalls.

Mettler-Toledo Launches 100% Automated Label Inspection Solution Suite

Mettler-Toledo Product Inspection has recently launched a complete, fully automated label inspection solution for food manufacturers. The new portfolio, which includes the V13 Flat Pack Label, CV, and CMV Combination, inspects 100% of products and shapes, identifying 100% of label data and quality challenges. This solution is a cost-effective replacement for unreliable manual spot checks with 100% automated label inspection in high-speed production lines. It also helps achieve documented label inspection following industry guidelines such as BRCGS to support consumer safety and prevent expensive retailer fines and recalls.

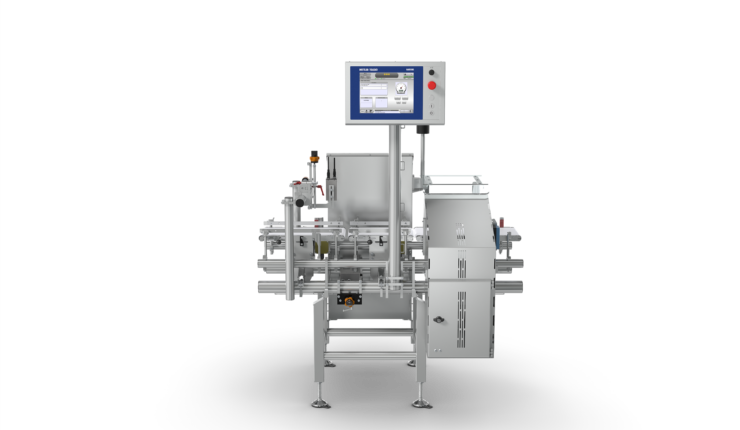

Flexible and easy to integrate into existing production lines, the V13 Flat Pack Label Inspection system is the highlight of the portfolio, featuring bottom inspection functionality. It can be combined with other Mettler-Toledo product inspection devices, such as checkweighers, metal detectors, or x-ray systems, offering solutions that are tailored to each production line.

Neil Gruettner, Business Development Manager, Vision Inspection at Mettler-Toledo, states, “We are very excited to be launching our new label inspection technology offering. The 100% automated label inspection portfolio is fully flexible and offers solutions that can easily be integrated into existing production lines.” The solution can be installed as an installation kit or as a standalone system, replacing manual spot checks with a more reliable and efficient inspection system, reducing rework, recall risks, and retailer fines.

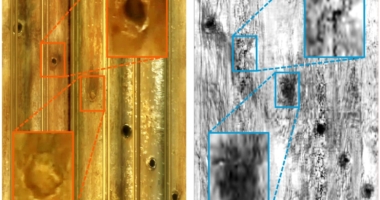

Manufacturers face many challenges regarding label data and label quality issues, from common operator errors to equipment malfunctions, including torn labels or ink smudging. These labelling issues can be challenging to effectively solve with manual spot checks. The new label inspection offering from Mettler-Toledo can reliably detect every non-conformity, whether it is ensuring the right product is in the right package, checking the readability of codes, or confirming the accuracy of ingredients, such as allergens.

In conclusion, the new label inspection technology offering from Mettler-Toledo provides a cost-effective solution for food manufacturers looking to improve their label inspection process while ensuring consumer safety and avoiding expensive retailer fines and recalls. The fully automated label inspection portfolio is flexible and easy to integrate, and with its reliable and efficient inspection system, it replaces manual spot checks to reduce rework and recall risks.

METTLER TOLEDO Launches Advanced Smart Cameras and Label Inspection Systems for Automated Inspection

METTLER TOLEDO, a global manufacturer of precision instruments and service provider, has launched a new offering for automated inspection technology in food manufacturing. The new portfolio includes advanced smart cameras and label inspection systems for efficient and reliable inspection of product labels and prints. The technology is designed to inspect oriented products from the side and top, allowing for a 360-degree inspection head to check round objects. The cameras can also inspect caps and lids, and can be mixed and matched to suit any production needs. The software is particularly user-friendly, featuring a dedicated toolset for label inspection that helps with product set-up. The new technology can be retrofitted onto existing Mettler-Toledo equipment, offering considerable space savings.

New Systems Overview:

V13 Flat Pack Label Inspection

The V13 Flat Pack Label Inspection system is robust, flexible, and space-saving. This solution carries out reliable label inspection from the bottom up to inspect labels on the underside of flat packs. The stand-alone solution offers configurable material handling options and can be extended with top and side smart cameras.

CV Combination

The CV Combination is an efficient weight and label inspection solution. The fully integrated system offers weight control and completeness check combined with label inspection for all product shapes. The space-saving solution is fully configurable from standardized modules and offers advanced quality control.

CMV Combination

The CMV Combination is an effective 3-in-1 inspection solution that delivers metal detection, weight control, and label inspection in one fully integrated and space-saving device. Its configuration is flexible and can be designed to match application needs.

The new portfolio from METTLER TOLEDO offers a cost-effective way to exchange unreliable manual spot checks with 100% automated label inspection in high-speed production lines. The solution helps to achieve documented label inspection in line with industry guidelines such as BRCGS to support consumer safety and prevent recalls and expensive retailer fines. With the advanced smart cameras and label inspection systems, manufacturers can ensure consistent and higher product quality, protecting both consumers and the reputation of manufacturers and their products and brands.

To learn more about METTLER TOLEDO’s automated inspection technology, visit https://www.mt.com/pi-pr.

Don’t miss interesting posts on Famousbio