The emergence of new trucking technologies presents a unique set of challenges for recovery specialists. Despite advancements in safety technology, accidents can still occur, making it essential to start asking the hard questions about “what if” and to ensure that measures are in place to address accidents as soon as they occur. Repairing new technologies presents unique challenges, and discussions on maintenance and repair are necessary. The importance of vehicle recovery and the need to consider the reality of the world, which is far more complex than we might want to acknowledge, must be emphasized. The key to addressing these challenges is for technologists, regulators, manufacturers, and fleets to work together to ensure that the necessary measures are in place to deal with accidents related to new trucking technologies.

New Trucking Technologies and the Challenge of Crashes

Developers of new trucking technologies are facing significant challenges, one of which is the failure to consider that trucks will inevitably crash and require repairs. While many are striving towards zero crashes, the reality is that accidents happen, and the real world presents numerous challenges.

Animal-motor vehicle crashes are a frequent occurrence, with 4.4% of all motor vehicle crashes being attributed to such accidents. It is for this reason that vehicle manufacturers have developed a standardized moose avoidance test protocol (ISO 3888-2), with variations including crash dummy moose or kangaroos, depending on the region. Massive front guards, also known as brush bars, bull bars, deer bars, moose bars, and roo bars, are a common sight on trucks worldwide.

The recovery teams depicted in the TV series Highway Thru Hell understand this reality, as they work tirelessly to keep the passes in British Columbia open, often encountering accidents that involve heavy-duty trucks. Even a low-speed crash can cause significant damage, as was the case with a bobtail semi that ended up in a ditch with a twisted chassis and front axle clocked 90 degrees to the rear tandems. However, the truck was able to roll away after being pulled out by a recovery truck and repaired in the yard.

While it is commendable to strive towards zero crashes, it is essential to consider the inevitability of accidents when developing new trucking technologies. The idealistic goals of multiple agencies and technology companies should not neglect the reality of the world, which is far more complex than we might want to acknowledge.

The Challenges of Repairing New Trucking Technologies

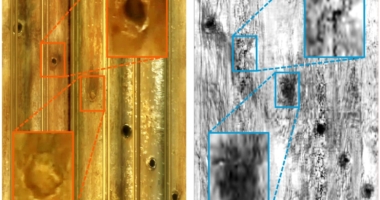

As new trucking technologies emerge, recovery specialists are facing a multitude of new challenges. What happens when a hydrogen fuel cell tractor is rolled over in a ditch after a high-speed highway departure? How do you deal with a battery electric truck that is jackknifed and blocking traffic in a snowstorm? What about an autonomous truck with a new moose hood ornament?

While engineers enjoy designing new things, the real world presents challenges that must be addressed. Vehicle recovery is only the starting point, as questions arise about how damaged vehicles can be repaired. Repairing new technologies presents unique challenges, as demonstrated at a recent Technology & Maintenance Council (TMC) spring meeting where experts discussed electric truck battery safety and the need for further discussions on maintenance and repair.

Despite advancements in safety technology, accidents can still occur, and it is essential to start asking the hard questions about “what if.” The technologists, regulators, manufacturers, and fleets must work together to ensure that the necessary measures are in place to address accidents as soon as they occur, including those related to new trucking technologies.

Don’t miss interesting posts on Famousbio