General Motors’ engineers use virtual technology and simulators to develop and test vehicles before building prototypes. The Milford Proving Ground in Michigan is home to GM’s high-speed test track, and nearby buildings house engineers who refine and tune various systems to meet goals. Simulation can help speed up the development process and is a long-term investment for GM that will ultimately help it offer more affordable vehicles. According to Alan Amici, CEO of the Center for Automotive Research, “simulation is a way to improve time to market.” Testing in the virtual world allows engineers to work out problems and make changes before cutting steel and building prototypes, which saves time and money. The virtual technology is also safer and can run 24/7, which accelerates the testing schedule. Engineers can input data from any GM facility in the world and use virtual technology to test it and provide feedback on ways to improve it.

General Motors’ (GM) virtual simulation lab, located at the Milford Proving Ground, is the key to its electric vehicle (EV) future. This technology was first invested in by GM about six years ago, and it allows the company to simulate real-world driving scenarios and fine-tune vehicles and invent new technology. GM has borrowed an idea long used in the race car world, and the process helps the automaker deliver better cars to market, faster and at a lower cost. The company’s goal is to make more EVs affordable, and it plans to bring 30 new EVs to global markets by mid-decade and make Cadillac and Buick fully electric lineups by 2030.

GM is increasingly relying on virtual technology to gain an edge for its EV future. The lab allows GM to perfect ride, handling, safety and other innovations for upcoming EVs. This process is a cost-efficient way for the company to bring better cars to the market, faster and at a lower cost to the company. GM plans to pass on the cost savings to consumers.

GM’s cost efficiency is key to its strategy of making more EVs affordable for the mass market. The automaker offers Chevrolet Bolt EV and Bolt EUV, GMC Hummer EV pickup, and the Cadillac Lyriq SUV. The 2023 Bolt will start at $26,595, but it uses GM’s old architecture that will eventually be phased out. GM’s new EVs use the Ultium system for propulsion. The Lyriq starts at $62,990, and the Hummer EV3X on sale now starts at $99,995.

GM is aware that consumers need an incentive to switch from gasoline-powered cars to EVs. President Mark Reuss stated during GM’s investor day in November in New York that the company has to remain the automaker that reduces friction for buying an EV product. This includes price, package, design, usability, and range.

GM spokesman Stuart Fowle stated that the company is considering using virtual technology for everything that was previously done with physical tests. The shift to virtual technology will continue to grow over the next couple of years. GM is counting on consumers’ willingness to switch from gasoline-powered cars to EVs.

The virtual technology is not unique to GM, as most automakers use it to some degree. However, GM is increasingly relying on it to gain an edge in the EV market. The Detroit Free Press plans to look at virtual technology in part three of this series on the GM Milford Proving Ground.

General Motors (GM) has a state-of-the-art testing facility located in Building 144, where a team of engineers work day and night testing and analyzing data from a matrix of computers and machinery. The lab is a labyrinth of large interconnected computers with bright fluorescent lights shining down. GM’s lead performance engineer for Virtual Vehicle Dynamics, John Wilkinson, states that the lab’s primary testing is called “open-loop,” which means that the engineers can test just about any scenario or vehicle part virtually.

The lab’s virtual technology enables engineers to test things very quickly, and they can run many iterations. Wilkinson says that they can actually do more testing than they traditionally could do with just a prototype vehicle. The lab’s team of engineers can program tests to simulate various scenarios such as pressing the brakes, testing the function of anti-lock brakes, stability control, and any other scenario a driver can think of.

Next door to the Vehicle Performance Testing lab is the Driver-in-the-Loop Laboratory. This lab is like a mini NASA control center with two rows of stadium seating set behind a panel of technical controls manned by four to five engineers. Behind a glass partition sits the simulator, a car with two seats, a steering wheel, a throttle, and brake set about 5 feet off the ground atop a “motion table.” The platform simulates the road surfaces that the vehicle testing lab tells it to do. GM bought the simulator six years ago to use for Corvette development.

The two labs feed data to each other. Once the Vehicle Performance Testing lab completes a specific test, an engineer in the Driver-in-the-Loop lab climbs into the simulator to run driving tests on a specific vehicle incorporating those brakes in various road conditions. The facility’s cutting-edge technology allows GM to test just about any scenario or vehicle part virtually before it ever hits the road. The ability to do more testing than they could traditionally do with just a prototype vehicle helps GM to develop new technology faster and at a lower cost.

General Motors (GM) has invested tens of millions of dollars in virtual technology that enables engineers to test and perfect vehicles and invent new technology before the prototypes ever hit the road. GM has a labyrinth of interconnected computers where engineers input data and then analyze data from a matrix of computers and machinery. The lab’s primary testing is called “open-loop,” which means that the engineers can test just about any scenario or vehicle part virtually. GM’s engineers can simulate road surfaces and make decisions on angles and controls to refine and perfect the vehicles.

The virtual technology at GM allows engineers to test anything, even driving on the moon as they work to develop an electric moon buggy for future Artemis astronauts. Engineers have also used the simulator to create an entirely new suspension for the 2023 Cadillac Lyriq EV and refine the CrabWalk, a four-wheel steer mode that allows the vehicle to move diagonally. With virtual technology, GM can test broad scenarios without having to put a test vehicle on the road.

The speed to market advantage is priceless to engineers, according to Alan Amici, CEO of the Center for Automotive Research in Ann Arbor. Simulation is a way to improve time to market. The proving grounds are there to prove what you’re learning is real. At GM, the virtual technology allows them to do more testing than they traditionally could with just a prototype vehicle. GM’s new EVs use GM’s Ultium system for propulsion, and the process allows the automaker to deliver better cars to market faster and at a lower cost.

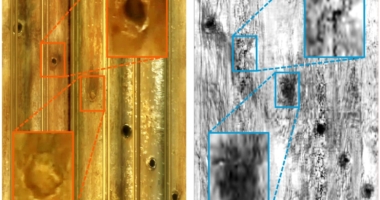

GM’s Automated Driving Performance Simulation Laboratory is nearby, where GM engineers use more computers to test and perfect GM’s hands-free driving technology called Super Cruise and other safety technology. The lab has recently added the Keysight Radar Scene Emulator that simulates real-world scenarios for radar equipment. Radar, along with cameras, allows for hands-free driving by telling a vehicle to stop or react to other objects on the road.

Keith Van Houten, engineering group manager for Automated Driving Simulation, calls it teleportation of the nerds. The technology can represent people, animals, and other cars on the roads and make them do what the engineers want them to do for testing. The technology is priceless to engineers, and all automakers are using as much simulation as possible to improve their time to market.

In conclusion, GM’s investment in virtual technology is their key to their electric vehicle future. The ability to test anything and refine and perfect it before the prototypes ever hit the road enables them to deliver better cars to market faster and at a lower cost.

The Role of Virtual Technology in GM’s Testing Labs

General Motors (GM) engineers work in a state-of-the-art testing laboratory where virtual technology plays a key role in developing and testing new vehicles. The Vehicle Performance Testing Laboratory at Building 144 in Michigan is a complex labyrinth of computers and machinery, where engineers test various scenarios and vehicle parts before they hit the road.

Testing with Virtual Reality

The lab’s primary testing is called “open-loop,” where engineers test virtual scenarios, meaning if they can describe it, they can test it. “We have many tests that we run where we can program something to, say press the brakes. It can run overnight. You can run hundreds or thousands of test conditions that test the function of anti-lock brakes, stability control … pretty much any scenario a driver can think of … we can program it to test here,” said John Wilkinson, GM’s lead performance engineer for Virtual Vehicle Dynamics.

Next door, in the Driver-in-the-Loop Laboratory, engineers use a car simulator to run driving tests on a specific vehicle incorporating newly developed parts. The simulator is a car with two seats, a steering wheel, a throttle, and brake set about five feet off the ground, atop a “motion table” that simulates the road surfaces.

Testing Hands-Free Driving Technology

GM’s Automated Driving Performance Simulation Laboratory is another building where engineers use more computers to test and perfect GM’s hands-free driving technology called Super Cruise and other safety technology. The lab recently added the Keysight Radar Scene Emulator, which simulates real-world scenarios for radar equipment. The machine allows GM to test broad scenarios with the radar without having to put a test vehicle on the road.

Teleporting Engineers from One Place to Another

The labs use virtual technology to input vehicle data from any GM facility in the world to test it and provide feedback on ways to improve it, whether for a US pickup or an electric vehicle (EV) in China. Keith Van Houten, engineering group manager for Automated Driving Simulation, called it “teleport” because the technology can represent people, animals, and other cars on the roads and make them do what the engineers want them to do for testing. It is not unlike a video game.

Benefits of Virtual Technology

Virtual technology is a long-term investment for GM, which has already helped its subsidiary BrightDrop develop its electric commercial delivery van, the Zevo 600, in a stunning 20-month time frame. Also, Cadillac was able to launch the Lyriq nine months sooner than expected because of the virtual technology.

The virtual tests GM does often run 24/7, which accelerates the company’s testing schedule. Virtual testing is safer than physical testing because there is no human on the road, and a simulator is not going to hit a real deer or run off a real road. The prototypes on the road can also provide feedback to the simulator for further testing.

Improving Time to Market

Speed-to-market is crucial because it allows carmakers to react quickly to consumer sentiment. The automaker that can get a newly designed SUV to market fastest will meet consumer demands and capture more sales. Also, the longer the development process, the pricier it becomes. Automakers have to make more prototype cars for testing, which can easily cost $100,000 each, and pay engineers extra hours to test them. Using virtual technology, engineers can simulate the road surfaces and make decisions on the angles that they have to choose, and what the controls have to be. “That’s a big enabler to improving time to market,” said Alan Amici, CEO of the Center for Automotive Research in Ann Arbor.

In the late 1980s and early 1990s, it generally took most automakers

General Motors (GM) is revolutionizing the automotive industry with virtual technology. GM’s engineers can now simulate the road surfaces and real-world scenarios for hands-free driving, vehicle durability, and new suspension design, among others. The virtual technology is helping GM speed up the development and production of new vehicles, improve time-to-market, and save on the cost of prototyping. This investment has helped the company develop the electric moon buggy, the Zevo 600 electric commercial delivery van, and launch the Lyriq nine months sooner than expected.

Virtual Testing

Engineers use virtual technology in labs to test and perfect GM’s hands-free driving technology, Super Cruise, and other safety technology. The Milford Proving Ground in Michigan is the perfect location for engineers to find flaws during vehicle development and fix them. They can test broad scenarios with the radar without having to put a test vehicle on the road. With the virtual tests, GM can also run 24/7, accelerating its testing schedule. The prototypes on the road can provide feedback to the simulator for further testing too.

Speed-to-Market

Virtual technology helps automakers speed up the development process, reduce the cost of prototyping, and make the most efficient use of their engineers. In the late 1980s and early 1990s, it generally took automakers about five years to develop a new vehicle and get it to market. Now, thanks in part to virtual technology, it’s closer to two years, and the vehicles are more durable. Simulation is a way to improve time-to-market, said Alan Amici, CEO of the Center for Automotive Research in Ann Arbor. Automakers have to react quickly to consumer sentiment, and the one that can get a newly designed vehicle to market fastest will meet consumer demands and capture more sales.

Attention to Detail

The virtual technology allows engineers to refine or tune their assigned system to achieve the goals set by the vehicle chief engineer. The job of the vehicle development engineers is to make sure that every measurable performance metric associated with the vehicle is met, such as durability, performance goals for every subsystem, and every area of the business case. The same kind of attention to detail is poured into every system of the car: suspension, steering, engine, transmission, body sealing, seat comfort, and audio system, to name a few.

Infinite List

The vehicle development engineers may face conflicting goals such as meeting a certain fuel economy while hitting a high-performance goal of 0-60 mph or meeting three goals for the doors. The door has to close effortlessly, but it should be heavy enough to block out wind noise and sealed to prevent water leaks. They must refine or tune their assigned system to achieve these goals. The same kind of attention to detail is poured into every system of the car, and the list goes on almost infinitely.

In conclusion, virtual technology has been a game-changer for the automotive industry. With its ability to simulate road surfaces and real-world scenarios, engineers can refine every measurable performance metric associated with a vehicle. The investment in virtual technology has helped GM develop its electric moon buggy, electric commercial delivery van, and launch its Lyriq nine months sooner than expected. The technology has allowed GM to speed up the development and production of new vehicles, reduce the cost of prototyping, and make the most efficient use of their engineers.

Don’t miss interesting posts on Famousbio